Kfz 17/1 restoration part 2: Body woodwork

A number of original body parts were used to re-engineer and reconstruct the woodwork for the body. Unfortunately the wood of the original parts was too degraded to use in the actual restoration. I wanted to be able to drive the restored vehicle; especially when driving through rough terrain the body is subjected to severe stresses and the joints between old and new wood will not survive for long. Large parts of the body were pre-fabricated in Germany, but a number of adjustments were needed when fitting the body onto the chassis. Also new construction details about the construction were learned in the years it took to get to this point, so a number of improvements could be made to the framework.

As far as possible, the details were copied from original parts. This allowed the exact dimensioning of the floor panels and the internal deviding walls inside the vehicle. Especially in building the numerous storage compartments, the original equipment was needed to ensure a proper fit. Once all the details of the frame were correct, the exterior pertinax panelling could be attached. The panels are attached with wood screws, original panels and detailed photographs were used to replicate the exact numbers and placement of screws. I did deviate sligthly from the original specification by using stainless screws. Due to the moisture retained in the wood it was found that the mild steel hardware started to corrode very quickly. This corrosion and subsequent weakening of the wood was one of the main reasons why the original wooden parts could no longer be used. I lost count of the number of wood screws used in the body, but a rough estimate would be about 2000!

Once the body panels were fitted attention turned to the roof covering and the guttering designed to keep the water out. As the work progressed, more and more detail was added, especially the window frames required a lot of detailed parts. It was a satisfying milestone when all the windows were in and the body was fully enclosed. After that the attention turned once more to metalwork as mudguards, engine covers, a-post and rear door were restored and fitted. The Kfz.17/1's antenna installation is what sets it apart from the Kfz.17: instead of a large roof antenna the Kfz.17/1 has a simple VHF rod antenna; under the rood of the vehicle is a network of wires to create a ground plane for the antenna.

In the spring of 2017 the "mechanically complete" milestone was achieved and thoughts could turn to the painting and detailing of the vehicle. Originally all Horch Kfz.17's would have left the factory painted dark grey. As the war progressed, vehicles would be touched up, resprayed and camouflaged by their crews. As I wanted to represent the vehicle as a late war western front vehicle, I decided to spray the vehicle in ordnance tan and apply some camouflage. I first decided on a green camouflage overspray only, but after a year I added "rotbraun" as well to end up with a typical "Normandy" three tone camouflage. Internal detailing of the vehicle is still ongoing, but I am planning to finish the final details of the restoration in the 2020 season

Bits of body....

Bits of body....

Starting with the frame

Starting with the frame

Internal walls

Internal walls

Starting the flooring

Starting the flooring

Exterior panelling

Exterior panelling

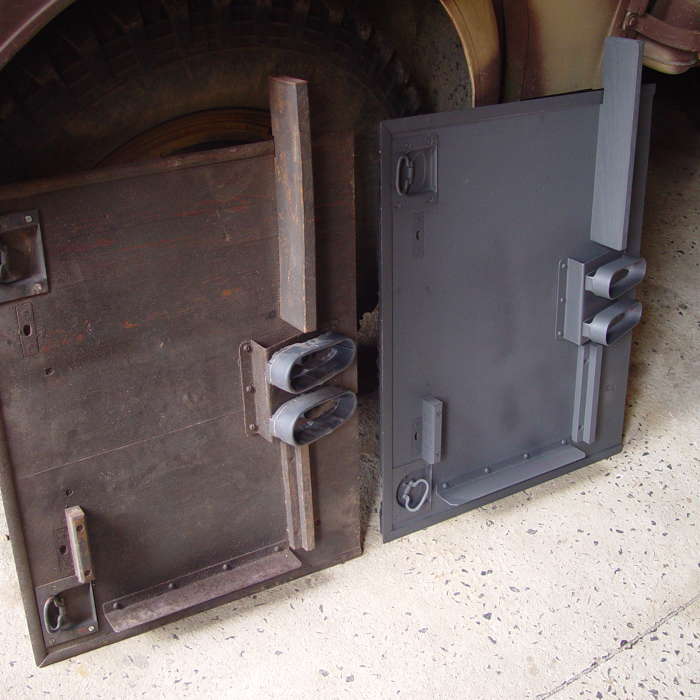

External door fittings

External door fittings

rear lid fitted

rear lid fitted Preparing the roof

Preparing the roof

roof insulation

roof insulation

roof covering

roof covering

and roof guttering

and roof guttering

External details

External details

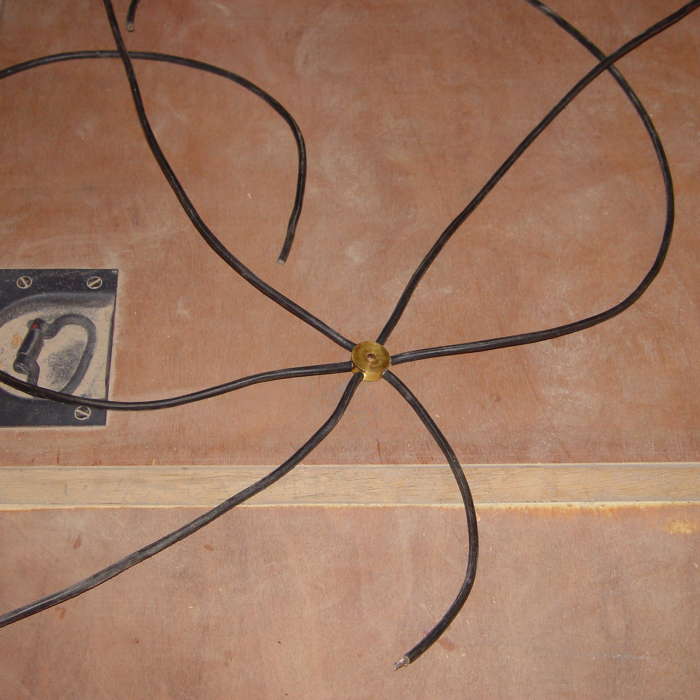

Antenna ground plane....

Antenna ground plane....

... and antenna

... and antenna

Interior panelling

Interior panelling

Internal door surrounds

Internal door surrounds

Interior electrical fittings

Interior electrical fittings

Front seats

Front seats

Front right floor panel

Front right floor panel

Dashboard surround

Dashboard surround

Central floor panel

Central floor panel

Central flooring

Central flooring

Rear seats

Rear seats

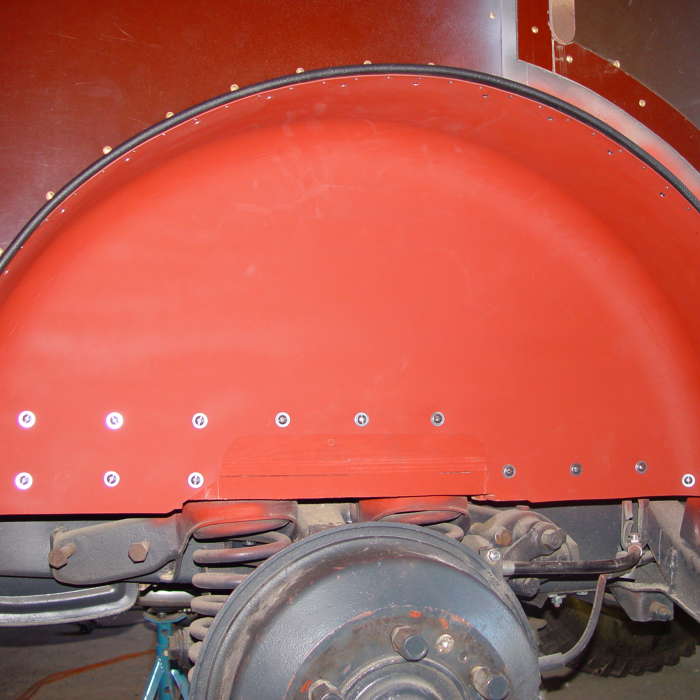

Rear inner mudguards

Rear inner mudguards

Luggage compartment left side

Luggage compartment left side

Generator brackets

Generator brackets

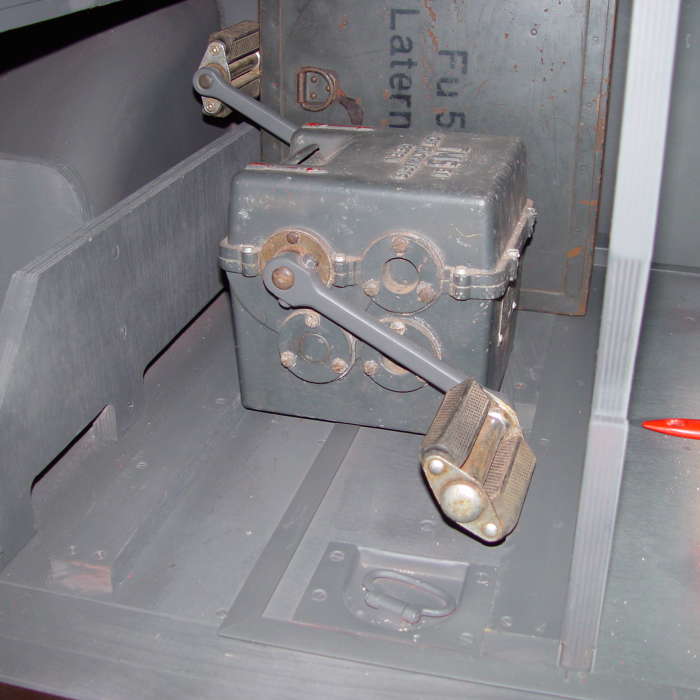

Fitting the Fu51 case

Fitting the Fu51 case Fitting the TM5 generator

Fitting the TM5 generator

Fitting the GG600 Generator

Fitting the GG600 Generator

Fitting the GG400 Generator

Fitting the GG400 Generator

Detailing the boot

Detailing the boot

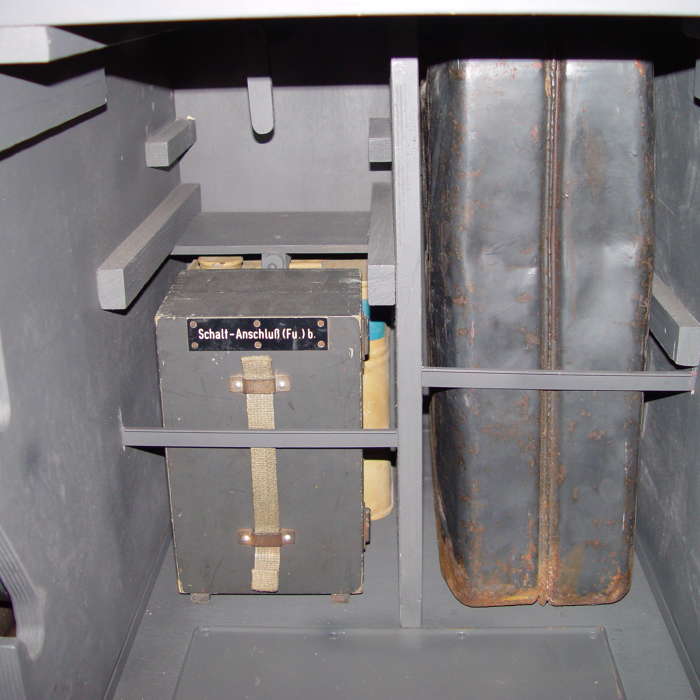

Fitting the equipment in the boot

Fitting the equipment in the boot